The Transport and Road Research Laboratory is set in a facility of about 800 m2 with some of the most advanced equipment for the mechanical characterization of innovative and sustainable road and airport materials.

The main fields of interest are:

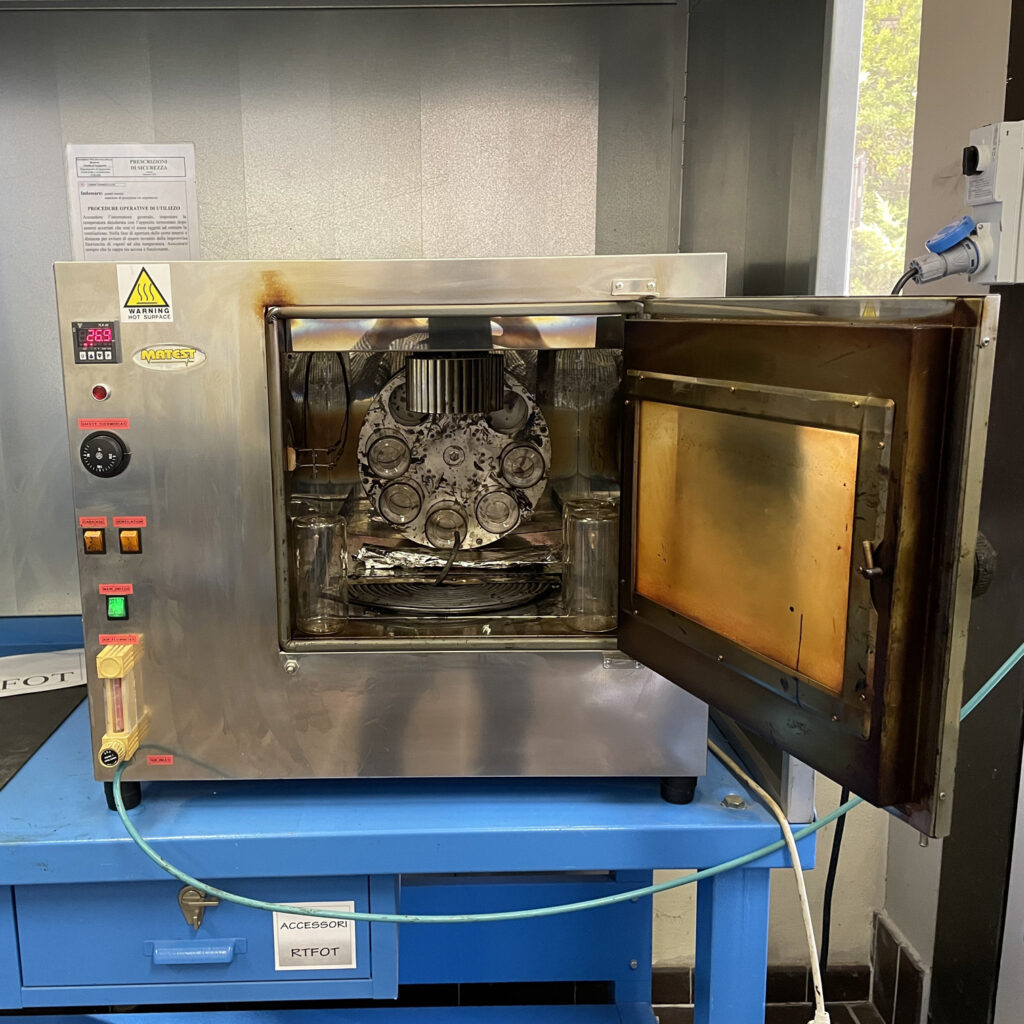

The Laboratory of Rheology of Binders performs test for the physical-mechanical characterization of bituminous and synthetic binders, bio-binders, and mastics.

Activities include the classification (according to both traditional and performance-based systems), rheological characterization (stiffness, fatigue, permanent deformation, thermal cracking), and the evaluation of durability (aging, adhesion, water susceptibility, healing) of binders.

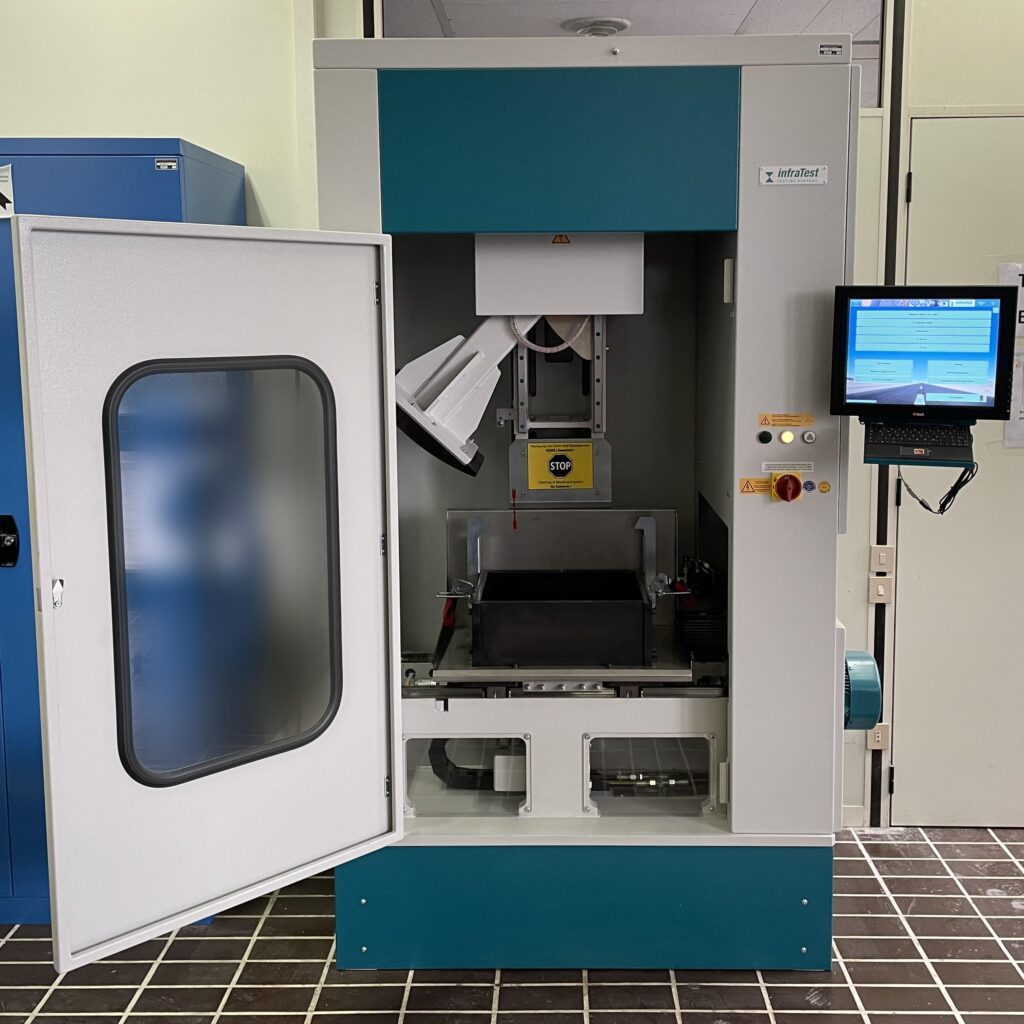

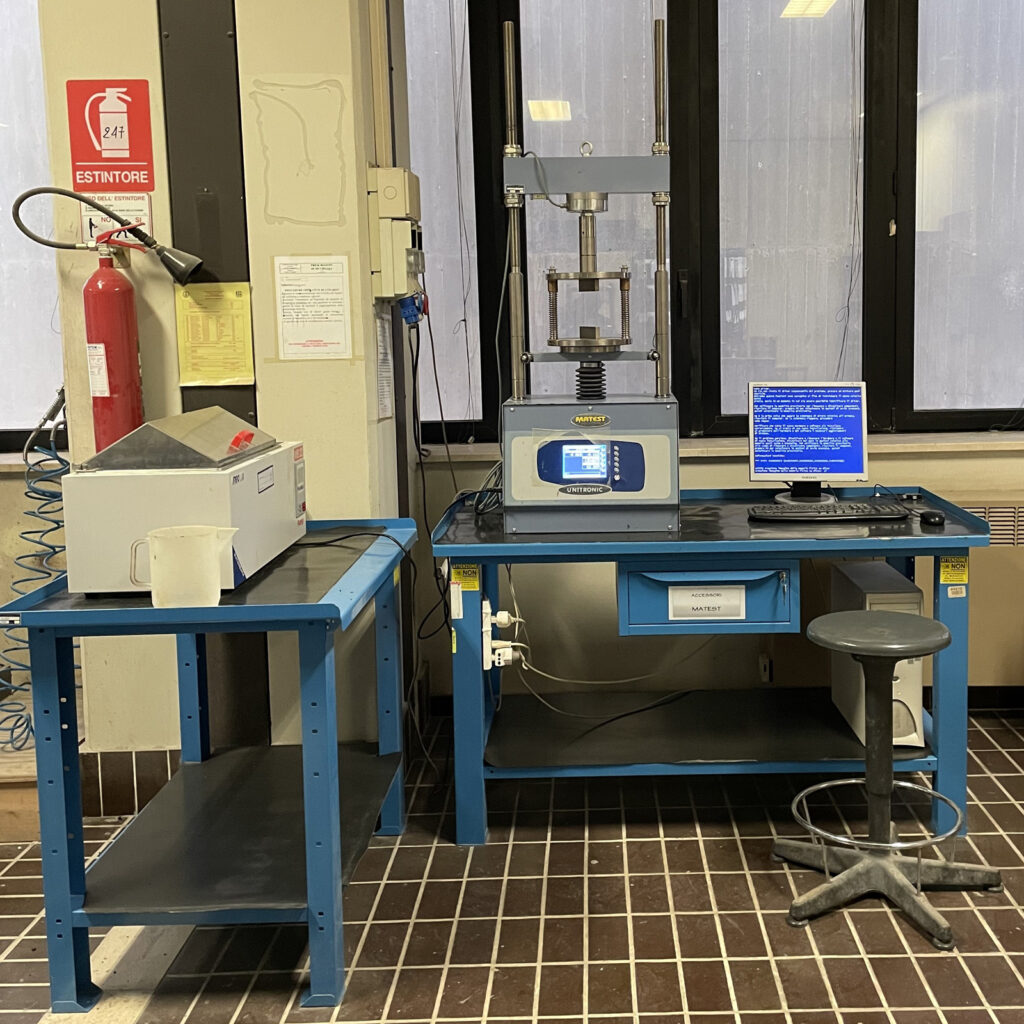

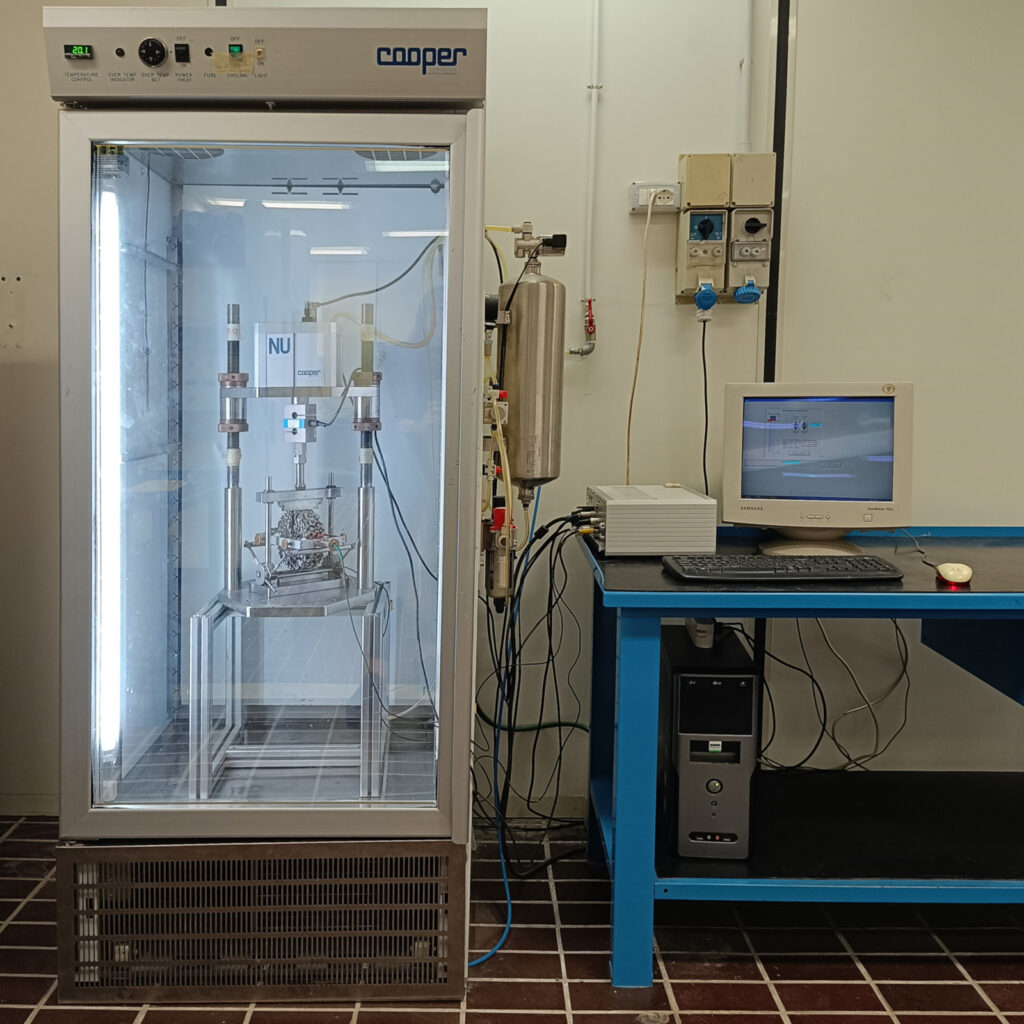

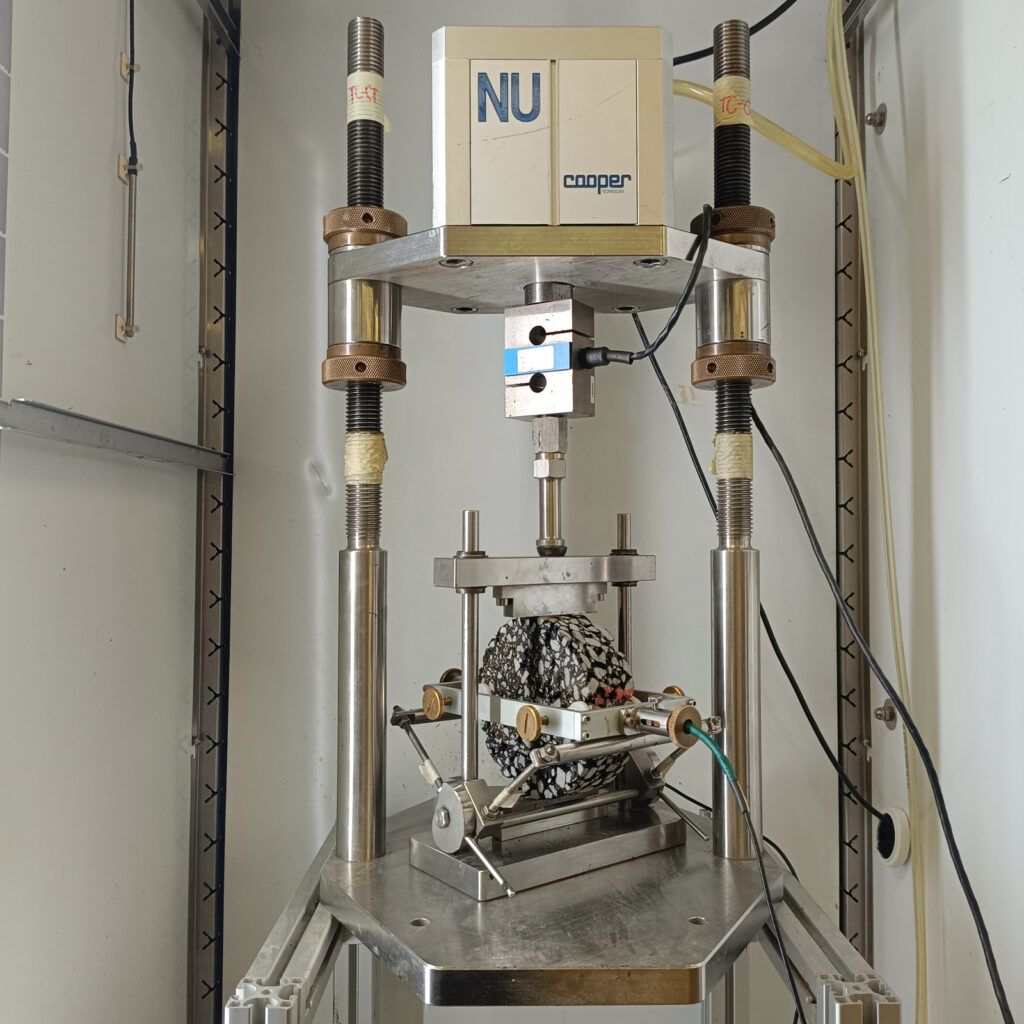

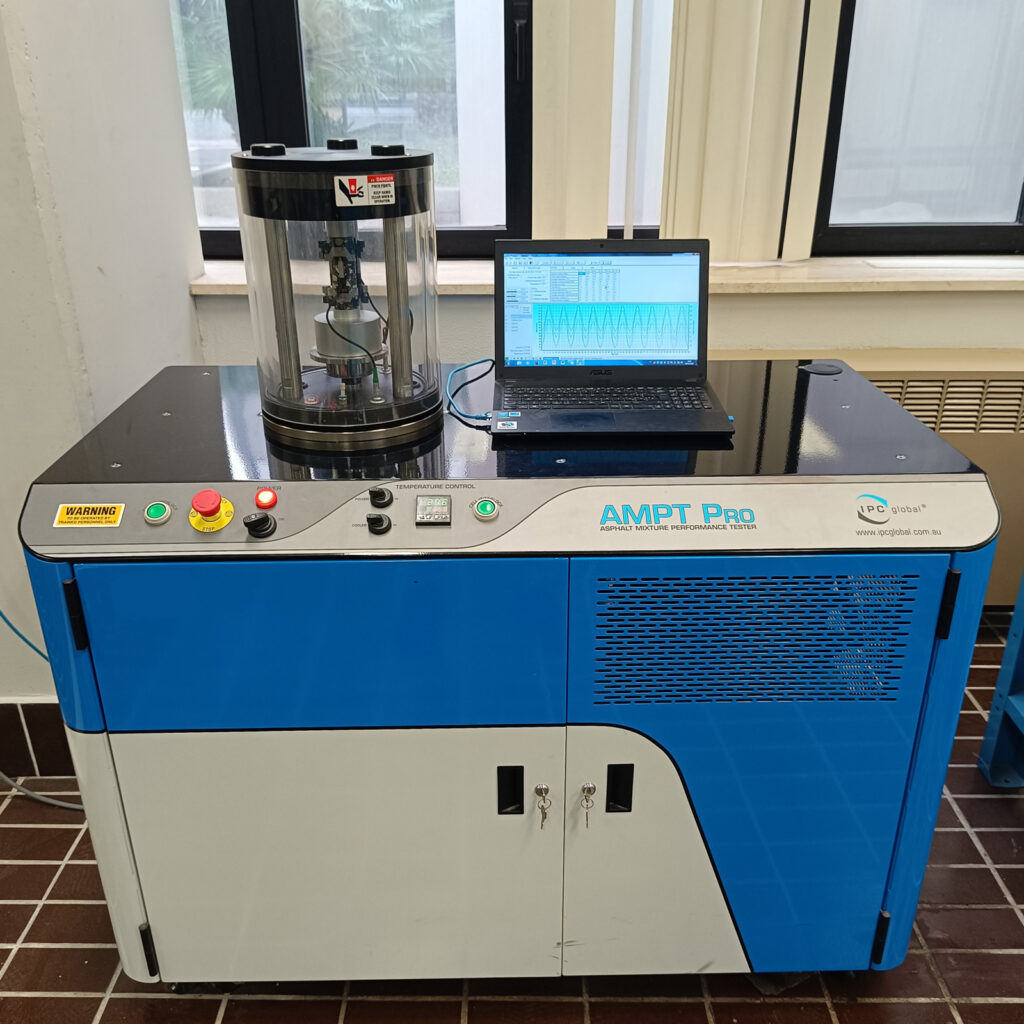

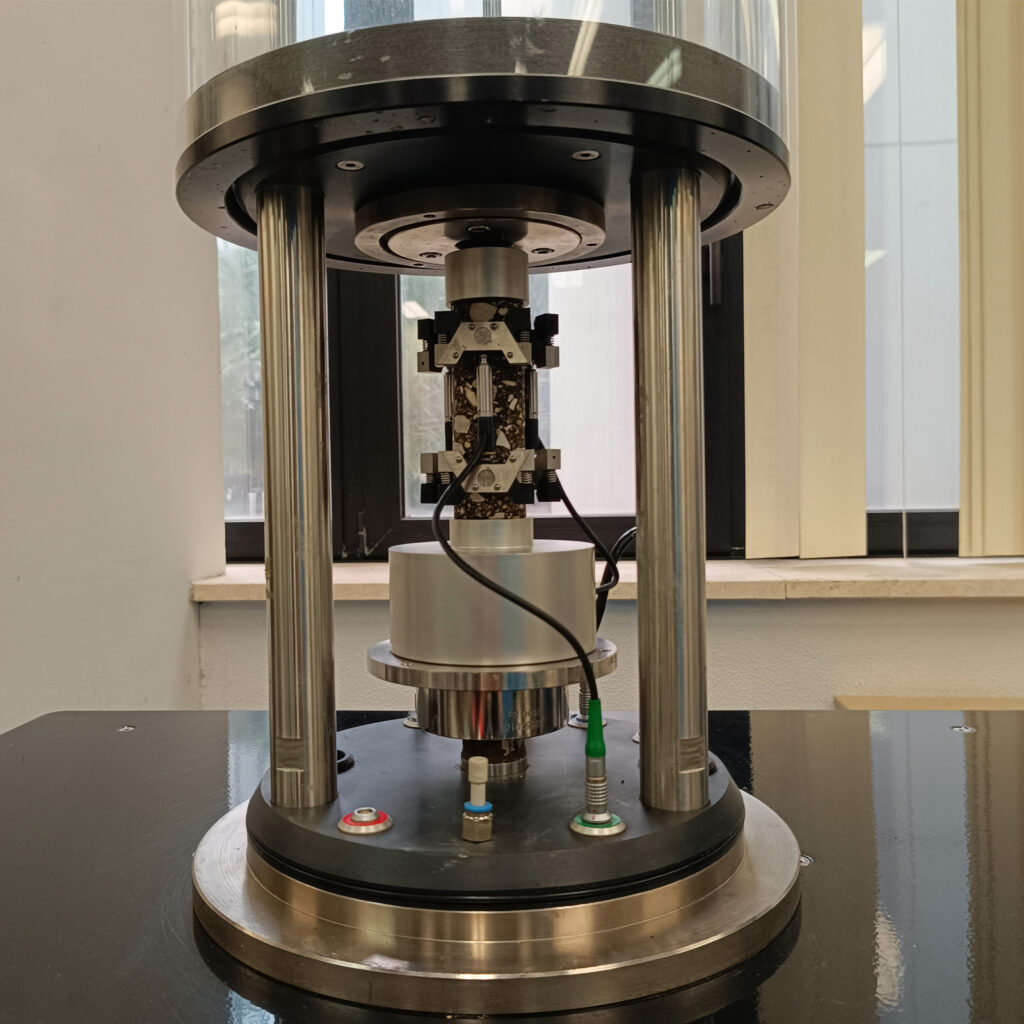

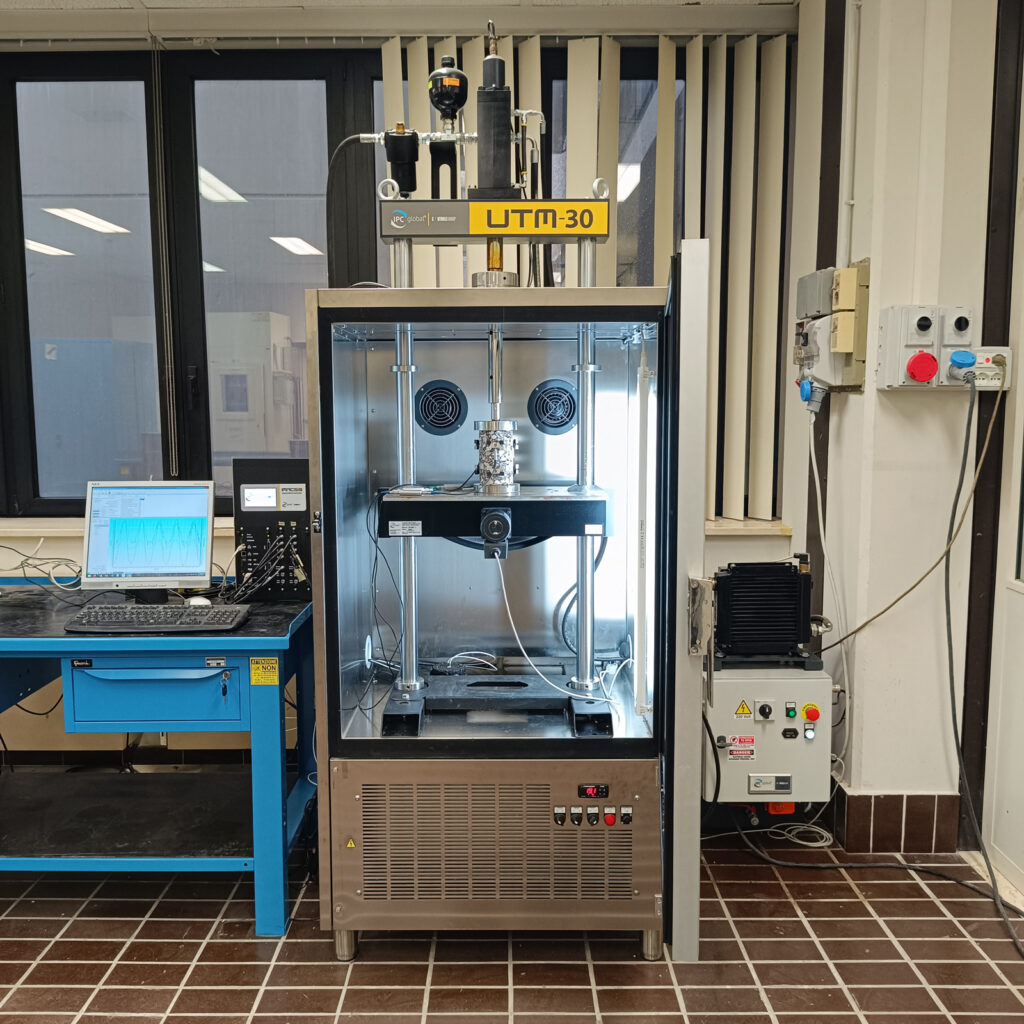

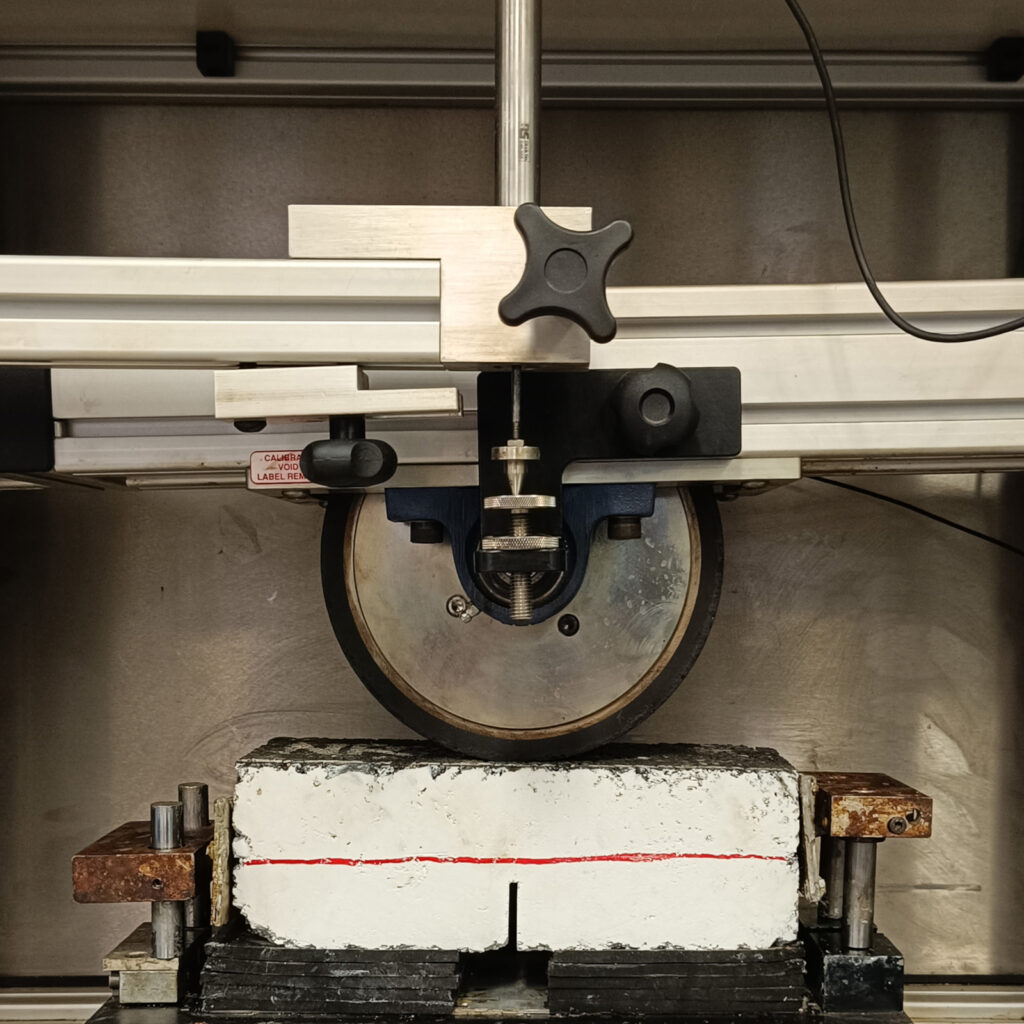

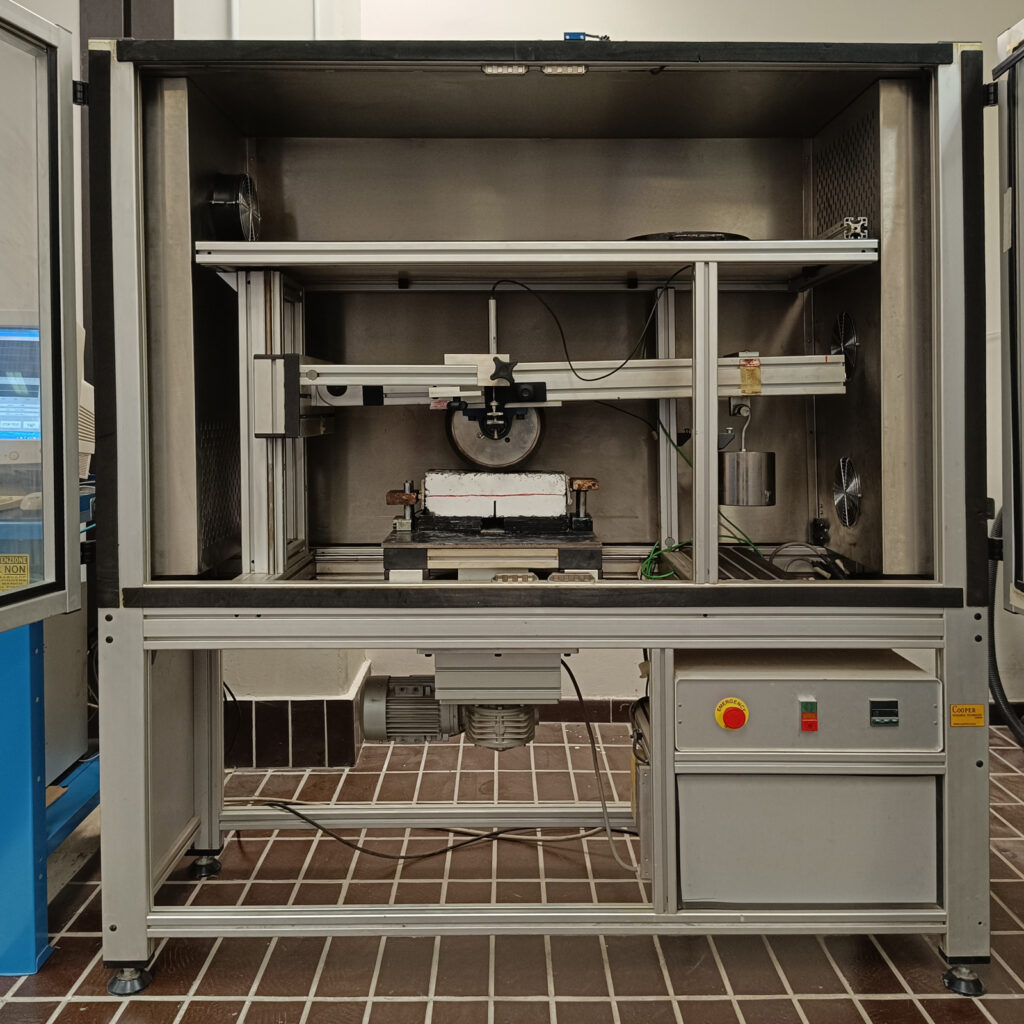

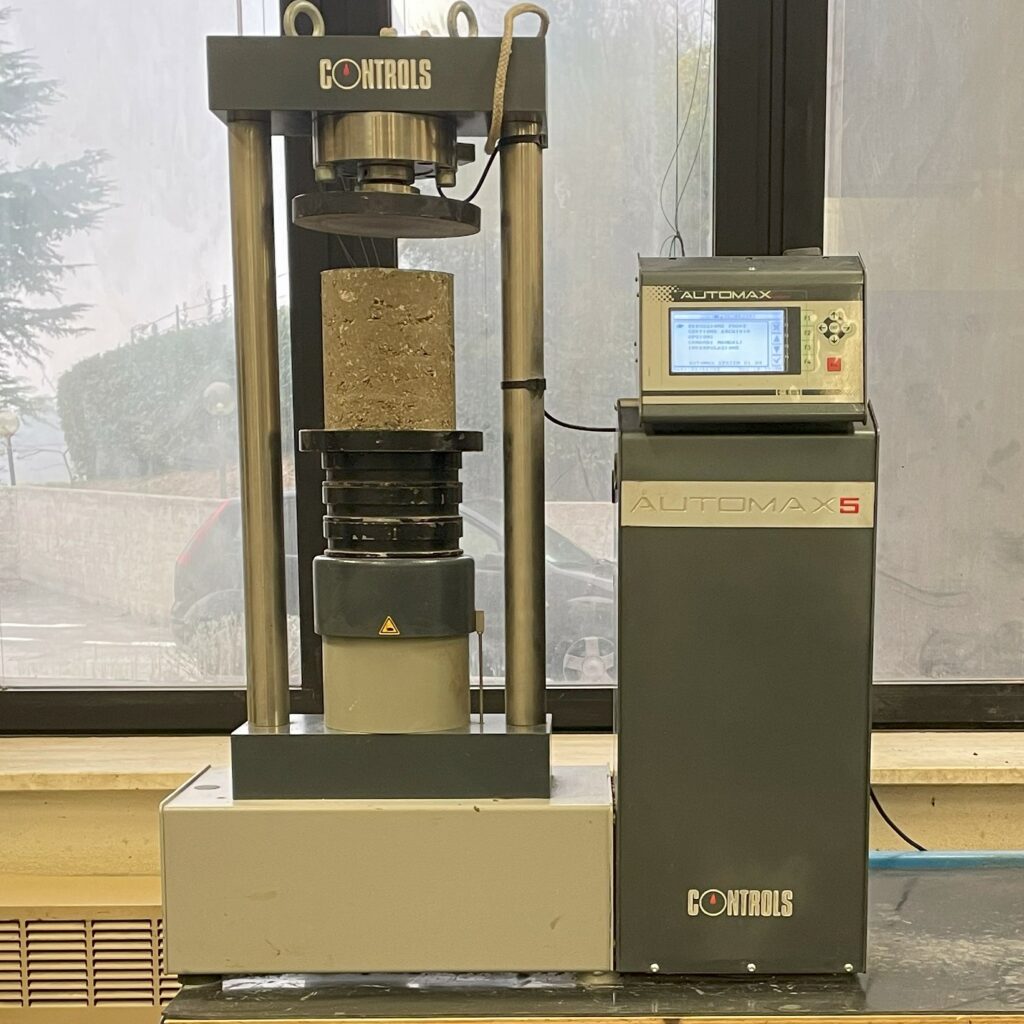

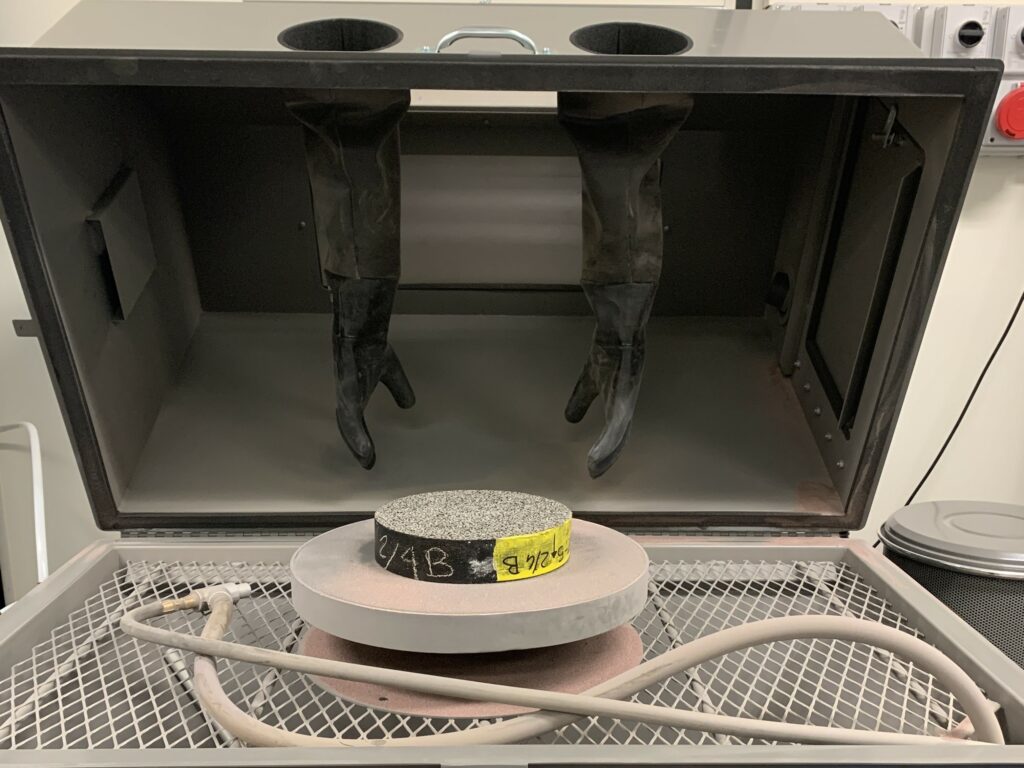

The Laboratory of Dynamic Testing for Mixtures uses the most updated dynamic testing equipment and prototypes for the mechanical characterization of traditional materials as well as hot and cold recycled mixtures, warm mix asphalt, considering both bituminous or non-bituminous binders.

Activities aim at determining the main properties of road and airport mixtures (strength, stiffness, fatigue and rutting behaviour, interlayer shear strength and water sensitivity) and studying the behaviour of reinforcement and waterproofing systems for road infrastructure.

The Laboratory of Geotechnics for Infrastructures performs tests for the physical-mechanical characterization of soils and mineral, manufactured and recycled aggregates.

Activities include the classification of soils, the physical-mechanical characterization of mineral, manufactured and recycled aggregates and the investigation on lime or cement-stabilised soils. Aggregates are characterized in terms of size, shape, fines quality, bulk density, fragmentation, wearing, polishing, and freeze/thaw cycles resistances.

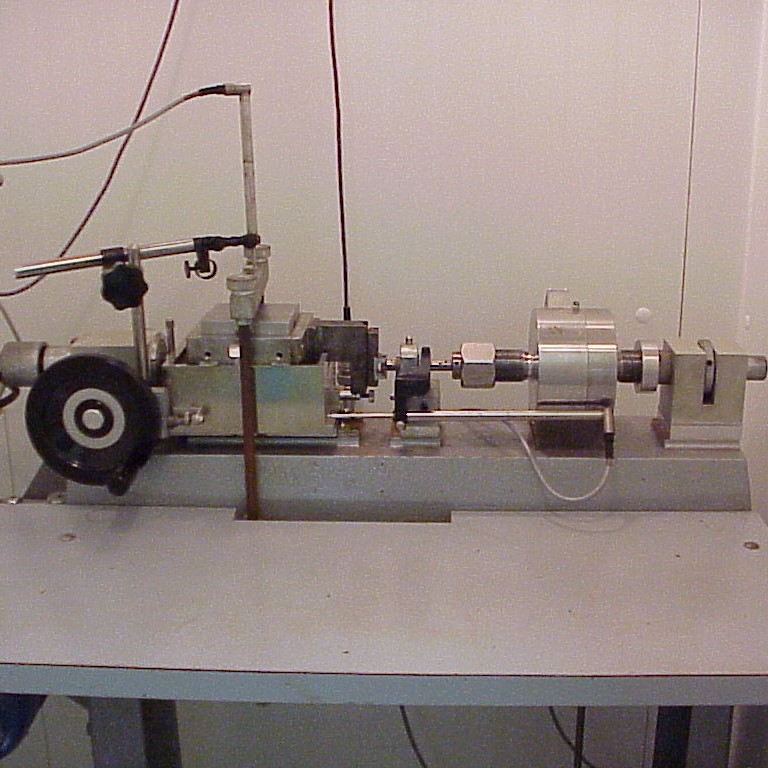

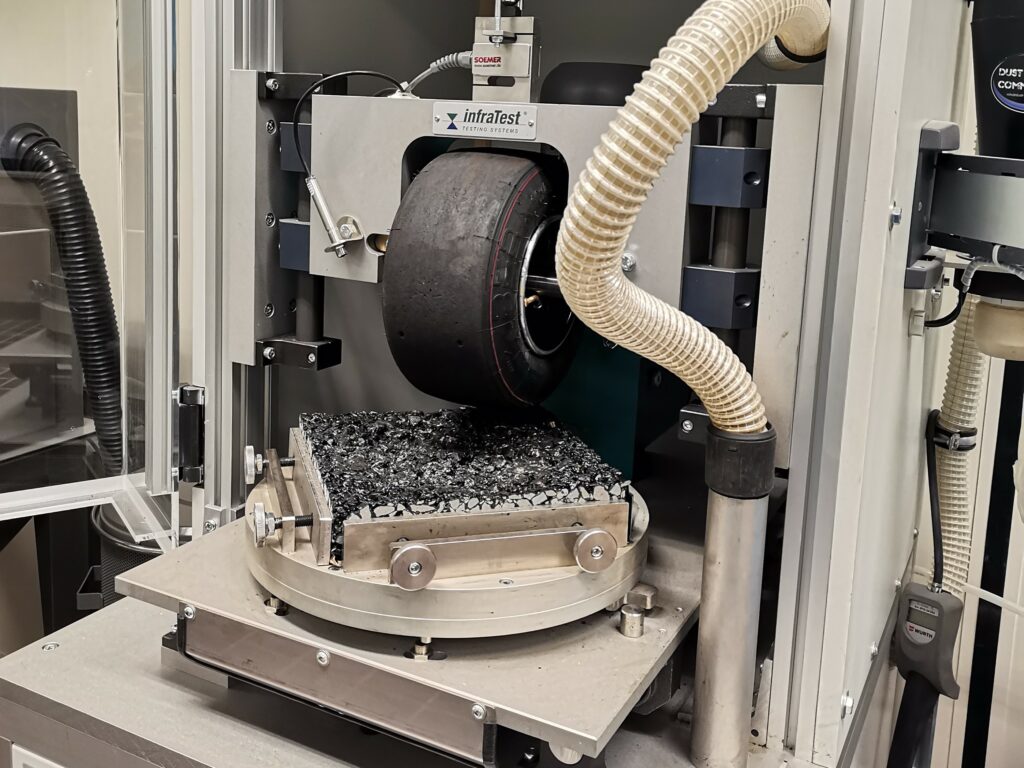

The MOST Laboratory focuses to the development of sustainable mobility, considering the safety of road pavements. Specific simulating machines allow the tire-pavement interaction to be determined.

Activities aim at evaluating the main pavement properties that affect user safety, including skid resistance/friction, polishing and ravelling characteristics of dense and open graded wearing courses.

Prof. Francesco Canestrari (scientific director)

Prof. Amedeo Virgili (head of the laboratory)